Students: Jort J. Leroij, Joël A. Bruinvels, Ixent Cornella Vilana , Guillermo Forcén Ordovás

Airborne Composites Automation announces a smaller version of the Automated Ply Placement (APP) robot cell, which can be used for optimisation and experimentation. Moreover, it can be displayed at fairs for customer sales.

The problem

The APP robot cell is fully developed and is ready for customer use. However, the extensive setup poses challenges for conducting smaller tests and experiments.

The fully assembled robot cell is not conducive to transportation. The current in-house Universal Robot lacks a sophisticated end tool and automatic programming features. Consequently, the robot showcased at the fair does not accurately represent the sophistication of the final deliverable product.

The Solution

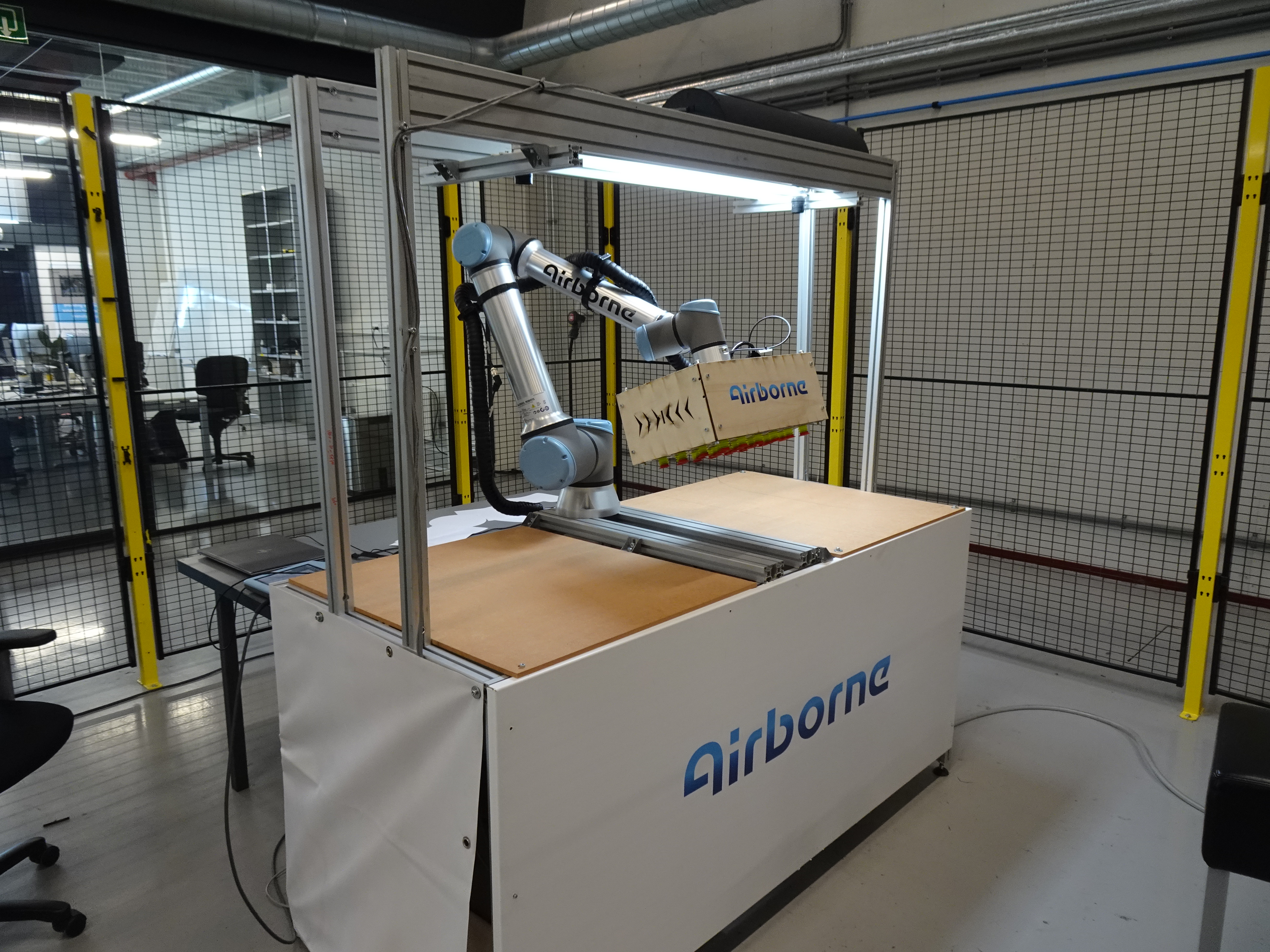

To address the need for an user-friendly and transportable setup for demonstrations and testing, a cobot system has been developed.

Firstly, the setup has been designed with lightweight and durable materials, such as aluminum, to ensure its portability and resilience. Specifically, aluminum profiles have been utilized for this purpose.The setup structure can be swiftly assembled and disassembled via a quick-connect system. This allows the setup to be easily adapted to different needs.

An Universal Robot (UR) was chosen for this project as it was already available in-house. Secondly, it is equipped with an intuitive User Interface (UI), which allow clients to operate the cobot with ease. Lastly, with a moderate weight of around 30 kg, the cobot is easily movable.

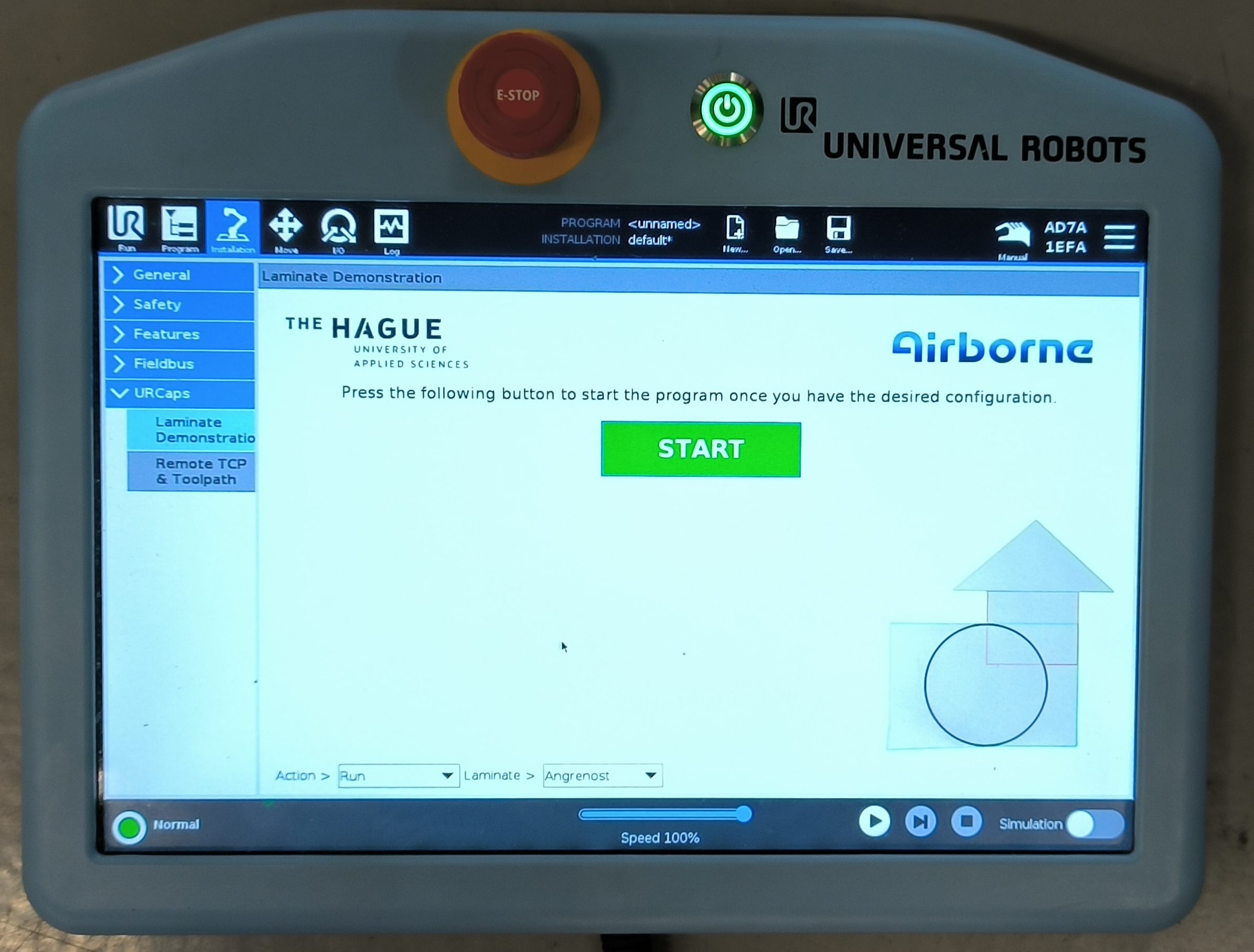

To further enhance user-friendliness, a custom UI screen has been developed. This UI has two possible programs, namely creating a laminate or calibrating the setup. For the creation of a laminate,severalpre-made options are available, conveniently displayed on the UI as shown in Figure 1.

To complement the setup, a new end effector has been constructed, equipped with a set of 24 suction cups. These suction cups can be easily switched out for different gripper types with a quick exchange system depending on the type of composite material that is used.

Figure 1: The custom created UI. The bottom left shows the currently selected program while and the currently selected laminate. The bottom right shows an image of that currently selected laminate.

A camera and sensor have also been integrated into the setup. The camera determines how the ply is positioned or orientated, allowing the robot to pick it up optimally by activating the relevant suction cups. The infrared sensor is used to verify that the ply is properly picked up.

In summary, our setup for demonstrations with a universal robot offers a comprehensive solution that meets the requirements of ease of use and portability. The entire setup is shown in Figure 2.

How does the robot operate

The setup consists of two main components: the cobot and a laptop. The laptop serves as the control hub, connected to the cobot, camera and the PLC, which is responsible for managing the vacuum cups. Most of the logic and calculations occur on the laptop, which then sends instructions to the cobot. For the cobot to operate, the laptop must be powered on and a Python file must be executed.

On the cobot, a UI has been programmed to include functions such as calibration and the creation of various pre-designed laminates from plies. Users can easily select their desired preform and initiate the process by clicking the ”green start” button. Before starting, the plies used in the preform can be placed anywhere in the working area. After the start button is pressed, the cobot is activated and creates the preform.

Customer quote

One of Airborne’s core products is the APP technology. This utilizes Airborne’s automated programming software, allowing for much higher flexibility then the current industry standard for machine building, which is an essential building block to automating composite production in aerospace. However, this concept is hard to explain in words, and therefore our clients need to experience the machinery. Since our complete production cells cannot be transported to trade fairs and is not always available, the students developed a small scale APP cell which demonstrated the process and how easy the process can be manipulated. This will give Airborne the opportunity to generate more revenue in the future by attracting more leads. Additionally, the flexible end effector concept is integrated bythe students into a small cobot end effector. This allows Airborne to conduct more derisking test, ensuring risks are identified earlier in the projects.

Figure 2: The setup with the Universal Robot and the custom made end effector. A lamp is added above the camera on the right for consistent illumination.