Students: Jefta Hofstede | Tom Hoogerwaard | Hanno van Megchelen | Sanne Thepass

Introduction

The planting company ‘Holding De Leeuw Ploegstraat B.V.’ plants cuttings to sell them after they have grown. Most parts of the planting process are automated, but the actual potting of the cuttings is still done by hand. EKB Groep Zuid, a company that delivers software solutions for the automation industry, asked us to think about a way to automate this part. During this project, we made a prototype for the process of planting cuttings.

Assignment

The potting process is now done by two employees, who pick up and plant the cuttings by hand. To save expenses, the company wants to automate this process with machines. Our assignment is to make a prototype for this planting process. The goal is to demonstrate the potential for using a Cobot in this situation.

The prototype must meet the following requirements:

- A robot arm, preferably a Cobot, is used to plant the cuttings

- Machine vision, a PLC and a HMI are integrated into the system

- The system is adjustable to different tray and pot sizes

- The speed of the robot must match the safety rules, so that it can work around employees

Our solution

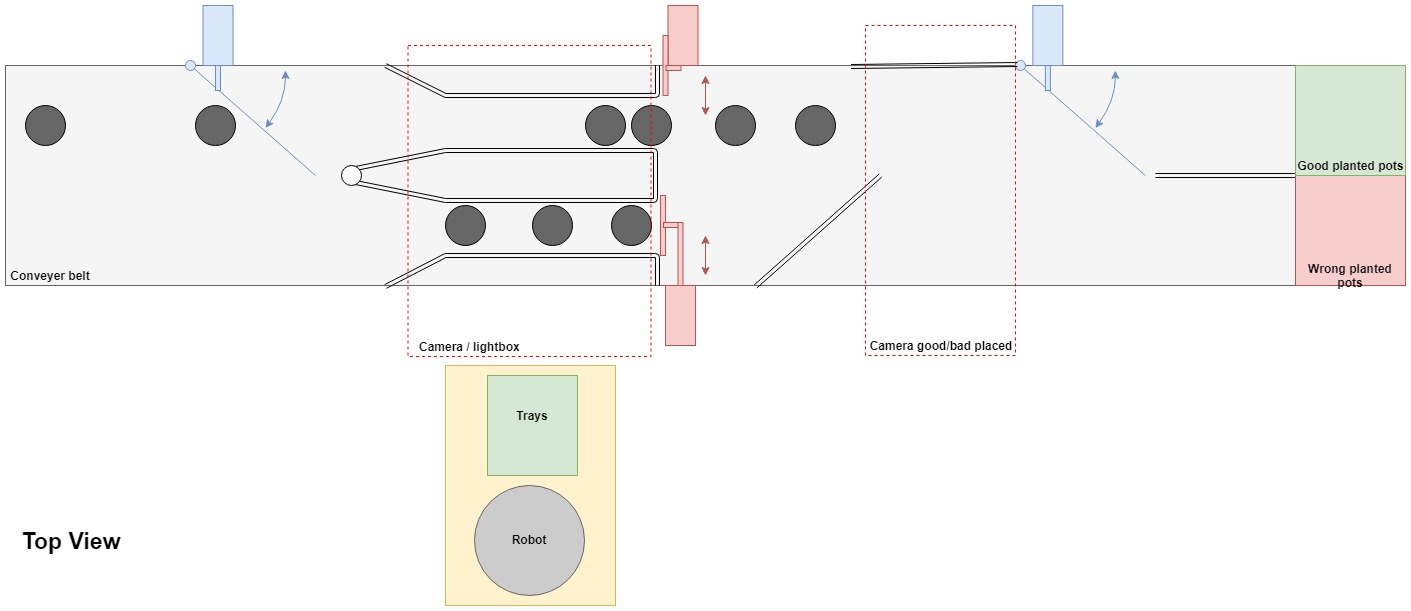

Our project team created a robust and adaptive system that uses a combination of mechanical, electrical and software components to plant the cuttings in pots. In Figure 8 the top view of the setup is illustrated.

The setup of our solution is divided in the following subsystems:

1. PICKING UP PLANTS

A robot arm is used to pick up plants from a tray and place them in the pots that pass by. The tray must manually be placed on the pin system beforehand.

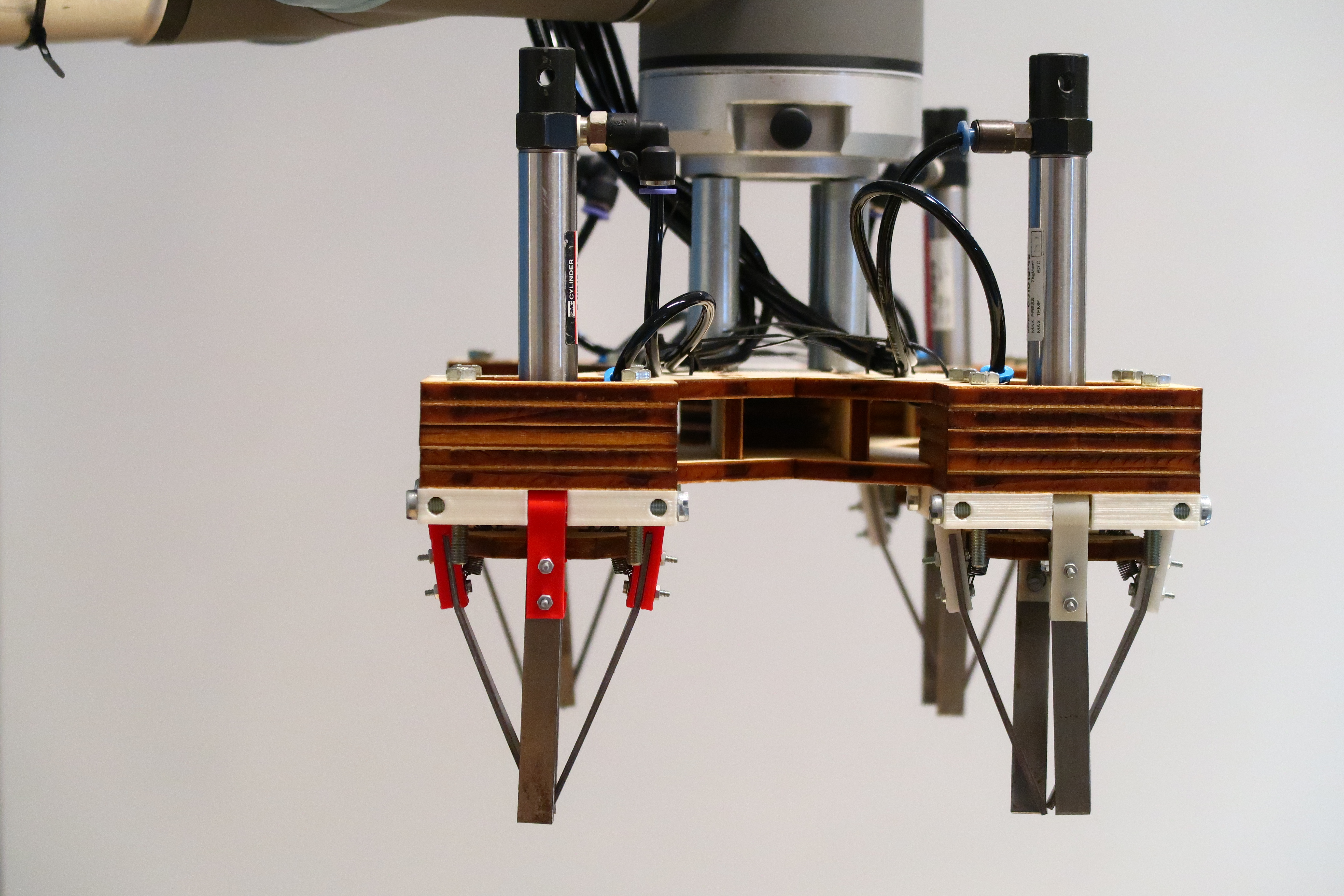

Picking up with grippers

The End-of-Arm tool is designed to pick up four plants at the time, to increase the potting speed. It has four grippers, where every gripper can be opened and closed individually by a piston (Figure 2). The End-of-Arm tool can be used for various tray sizes. Thanks to the spring system in the grippers, the plants can be picked up without being damaged.

The grippers of the End-of-Arm tool are driven by a PLC

Chessboard pin system

A difficulty that we encountered was the overlapping of plant leaves, which occasionally caused the grippers to pick up multiple cuttings at once. To tackle this challenge, we designed a chessboard pin system for the tray (Figure 3). By placing the tray on these pins, the cuttings will be separated by difference in height. Due to this difference, it’s easier to pick up the individual plants.

Pins push the cuttings out of the tray, to make picking them up easier. The robot plants all the higher cuttings before planting the lower ones.

2. PLANTING IN POTS

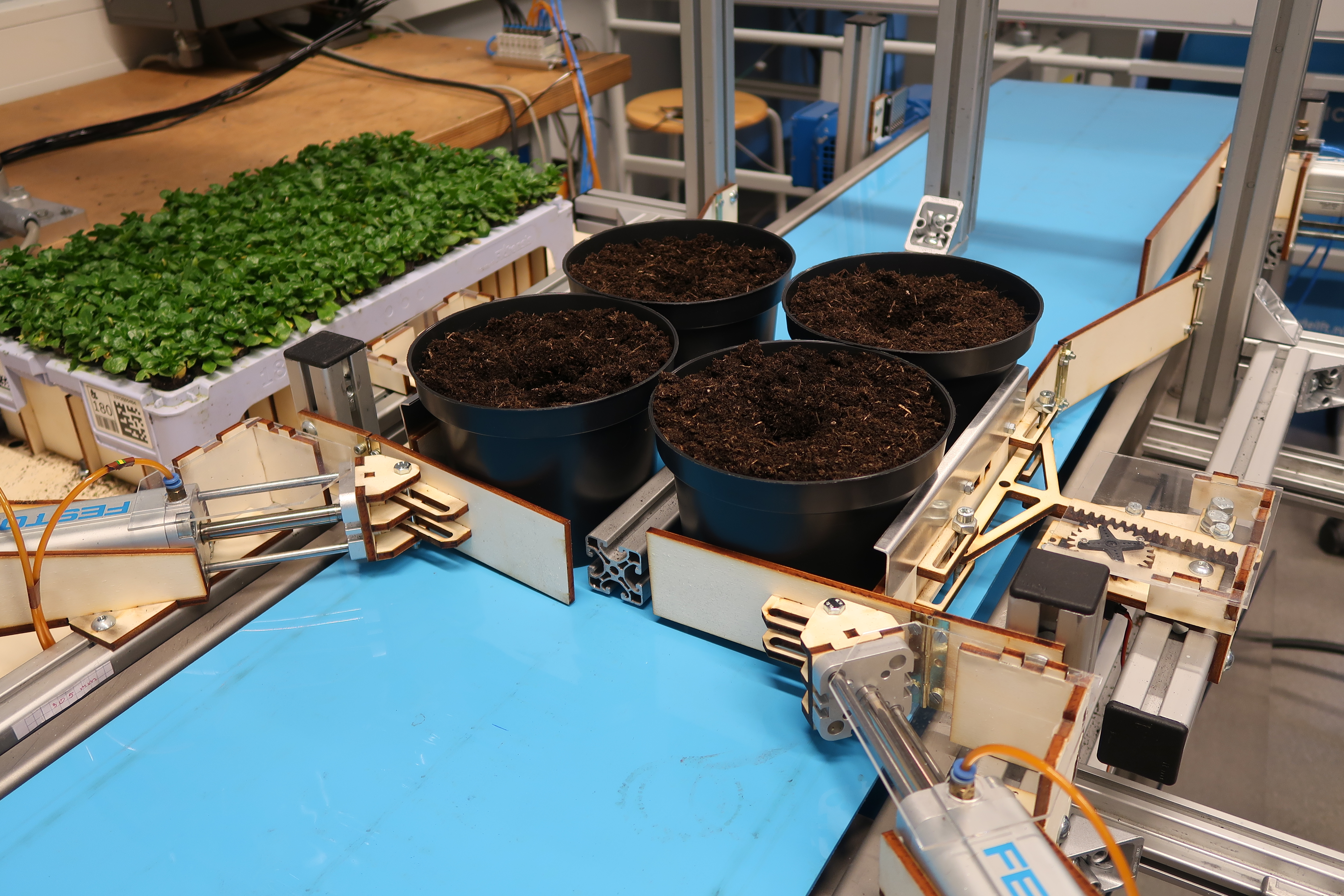

After the robot picks up four plants, it places them in four separate pots. These pots are transported on a conveyor belt and wait in a buffer to be filled. After this, the pots are sent further to a quality check. The pots are filled with soil and have a hole in the middle, where the cuttings easily can be planted.

Waiting in buffers

To speed up the process, we created a buffer system which divides the pots in two lanes (Figure 5). In each lane, two pots wait until they are filled with a cutting. After this, the pots are sent out to the quality check. When the lane is empty, new pots can enter. This buffer system works with two lanes that separately store pots, to improve the speed of the planting process.

Fixed positions

When the pots are in fixed positions, the cuttings can be planted more easily. To make sure that the pots are always waiting at the same location, a sizing system is added to center the pots (Figure 5). This system is suitable for different pot sizes, which can be adjusted with a HMI.

The pots are put on hold with the start/stop system, based on a slot guiding system that is shoved in or out by a piston.

The pots are kept in one place with the sizing system, which uses a servo to adjust the width.

To divide the pots in two lanes, a divider is integrated. It uses a laser sensor to detect pots and a piston to switch the direction.

3. QUALITY CHECK

Due to the variety of plants, some cuttings can be planted incorrectly. Therefore, a quality check is performed after the planting process.

Quality check

After the potting process, the pots are checked on quality. This is done with machine vision, using a Cognex camera. It checks if the cutting is planted in the pot and if no other plants came along (Figure 6). If the pot is filled correctly, it can be transported to an output buffer.

Incorrect pots

If a pot turns out to be filled improperly, it can be transported to a separate output buffer. This way, the incorrect pots get separated from the correct ones and can be fixed more easily. However, this is not applied in the prototype due to spacing issues. Instead, the results of the quality check are now displayed on the HMI (Figure 7). It indicates whether the filled pot is wrong and if so, what the error is.

The system can be controlled with the HMI. The pot size and tray size can be adjusted before starting a new batch. The results of the Quality Check are displayed on the HMI.

CONCLUSION

The project team has developed a prototype to display the automation of the planting process. A robust and adaptive system is built, that uses a combination of mechanical, electrical and software components to plant cuttings in pots. With a robot arm, cuttings are picked up and planted in with soil filled pots that wait in a buffer. After this, a quality control is performed to check if the plants were potted correctly. This prototype demonstrates how a Cobot can be used to automate a planting process.