Students: Mark de Roos, Elmer Russchen, Martijn Venselaar, Guus Zwart

Original situation

Forever Plants is a corporation that produces a wide array of plants. This includes dracaenas. To optimize

their product, Forever Plants hires people to remove the bad and dry leaves from the dracaenas. Leaves with brown tips with a minimum length of 5 mm or more are considered bad. This action is performed by 4 people during the day. The plants are brought in by a conveyor-belt. The workers grab the plant and inspect it for bad leaves. If detected, (partially) brown leaves are pulled of and the cleaned plant is put back on the conveyor-belt.

Assignment

We as a group got the assignment to work on a solution for the automation of the

leaf inspection and removal. This means we have to design and build a setup which is able to detect bad leaves and pull them out all by itself. The setup does not have to be ready for production purposes, but it should be a proof on concept. This means the setup does not have to match the speed of the workers at Forever Plants, it should only show it is capable of detecting and judging the leaves, as well as removing the faulty ones. The timespan for this project is 6 weeks.

Solution

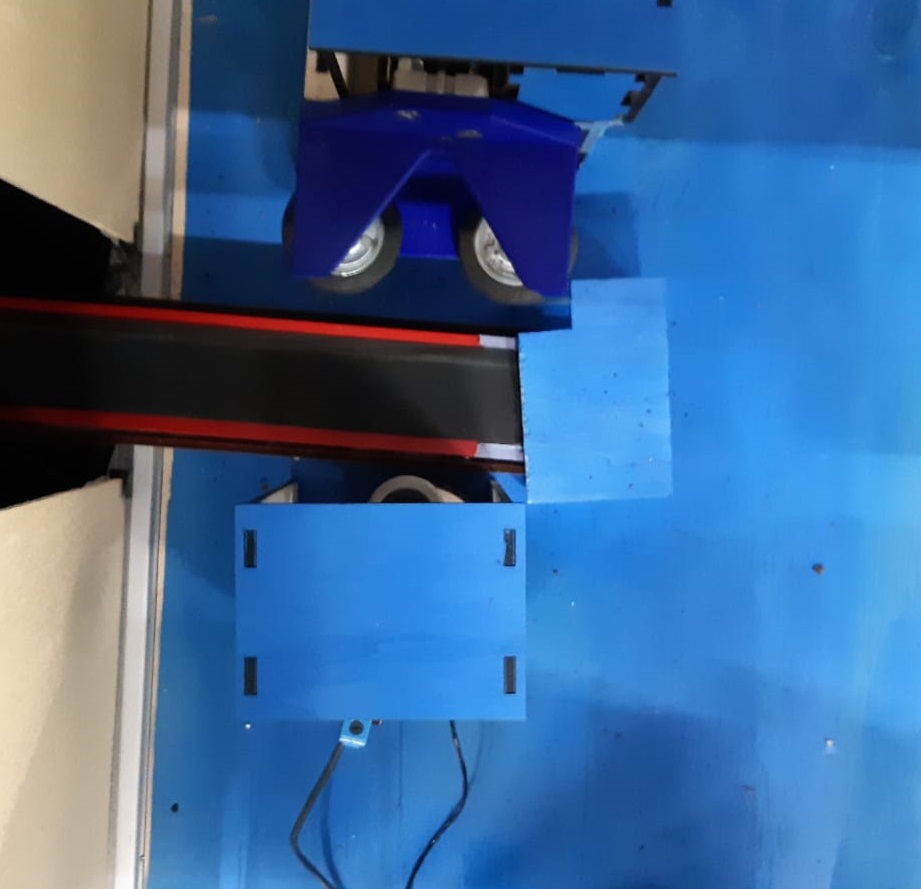

The plants are brought into the workspace by conveyor-belt. Here, the pot is held down by 2 pneumatic pistons which are controlled by a programmable logic controller: 1 pushes the pot against a wheel, while the other piston puts a lid over the pot to prevent vertical movement. After this, a 3D camera will take a picture and a 3D view and sends it to the PC. The PC filters the images to find the dry tips of the leaves. If the software detects any bad leaves, it will convert the pixels of the picture to real-life coordinates. These coordinates are sent to a FS03N Kawasaki robot. This is a robotic arm with 6 axis. It has a toothed end of arm tool, specifically designed to hold on to leaves without ripping them. The robotic arm positions itself over the detected leaf and lowers its gripper onto it. The PLC orders the gripper to close over the leaf. The leaf is pulled out and the process is repeated until the leaves in this part of the plant are removed. The PLC than commands the rotary wheel to turn the pot for several degrees and the process starts over. After no more bad leaves are detected, the pistons are retracted and the plant is led out by the conveyor-belts.

Major decisions

During the project, several big decisions were made. The first one was moving the robotic arm to a different spot in the box to create a bigger workspace and better possibilities to work around the plants.

Another decision was to focus mainly on the outer leaves of the dracaena. This was necessary because the leaves in the middle part were not distinguishable with the vision, for it just formed a blur with on the edge-detection and 3D view. In addition to this, the outer leaves tend to be the oldest and are most likely to have brown tips.

We also decided to paint the horizontal planes blue. Since we are using a red filter on the top-

view image , it is easier to filter out these planes. The red filter also highlights the brown tips since brown has a higher red-value than the green of the healthy leaves. This makes the bad leaves easily detectable with the naked eye and with machine vision. We chose to use the red filter in the code instead of using a lens, due to the complexity of fixing the lens onto the camera.

For the gripper at the end of the robotic arm we chose to use a schunk parallel gripper. We decided on this

gripper because it had a larger stroke than the other grippers we could choose from. After some trial and error grippers we decided on a gripper that was toothed with rounded edges. We chose for this design because other designs wouldn’t have enough grip to pull the leave out of the plant or the gripper would tear the leaves while trying to pull them out. We decided to add a dilation to the end of the gripper. We chose for this because of the following reason: during the positioning of the robot over the leaves it would sometimes miss the leaves. By adding the dilation we could minimise this problem and ensure a system that would work better.

A final big decision was about the movement made by the robotic arm to remove the leaves. The initial movement was pulling the leave up, for there is more freedom of movement for the robot above the plant. However, the leaves tended to rip apart during this. This led to the conclusion that it would be best to pull the leaves downwards.

Conclusion

We can conclude that it is in fact possible to automate the removal of bad leaves from dracaenas. The setup however doesn’t match the speed of the workers yet, and needs to be improved in order to remove leaves with smaller brown spots and remove leaves located at the center of the plant.

We would like to thank Forever Plants for offering this exciting assignment and providing the plants needed for testing.