Students: Bart de Langen, Jeremy Tiebosch, Roy Osephius, Hidde van Kleij

Introduction

Rexnord FlatTops Europe B.V. is a producer of assembly lines, conveyor solutions and flattop modules for customers all around the world. Our client’s devision (Rexnord FlatTops) is located in ‘s-Gravenzande, Zuid-Holland.

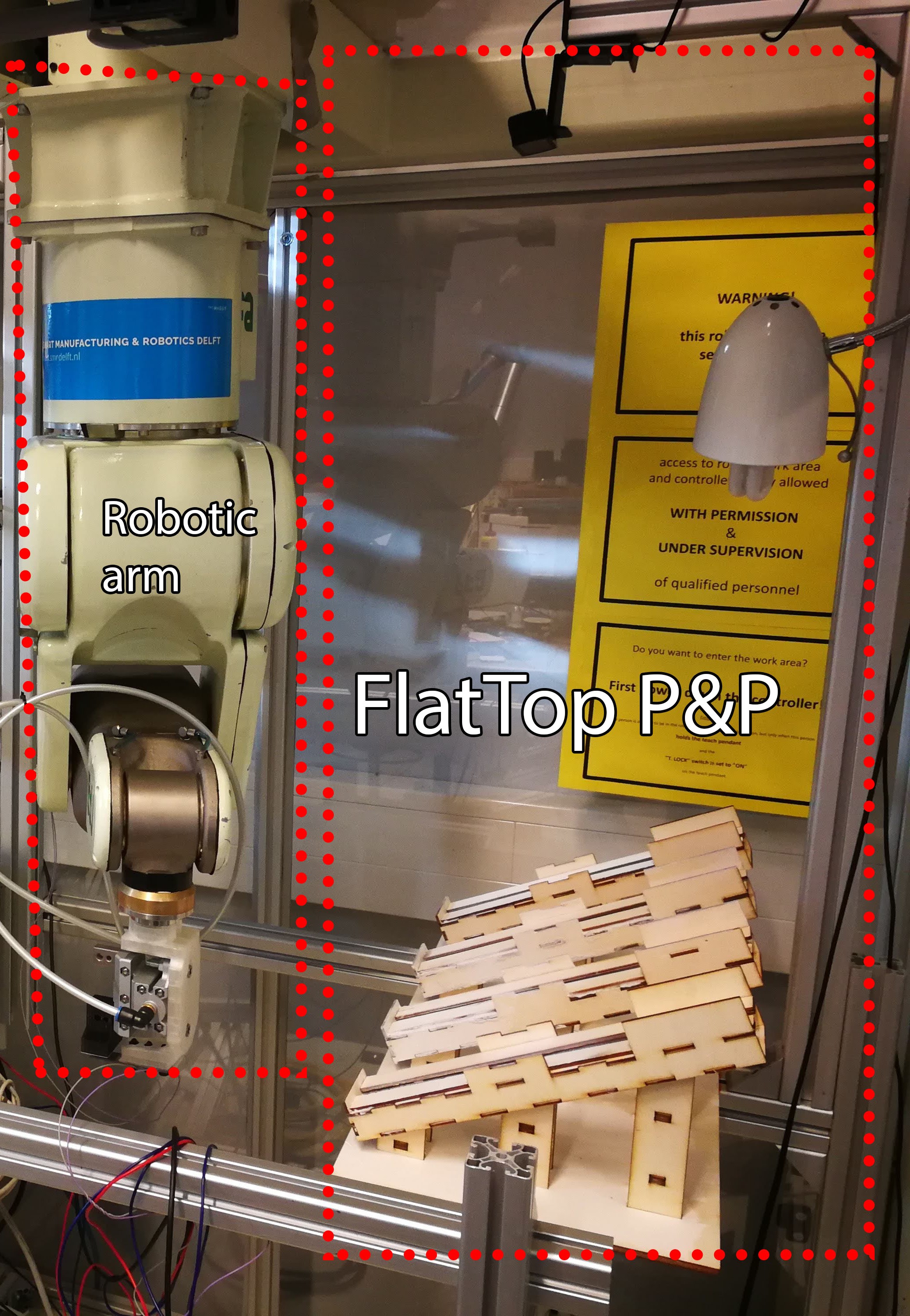

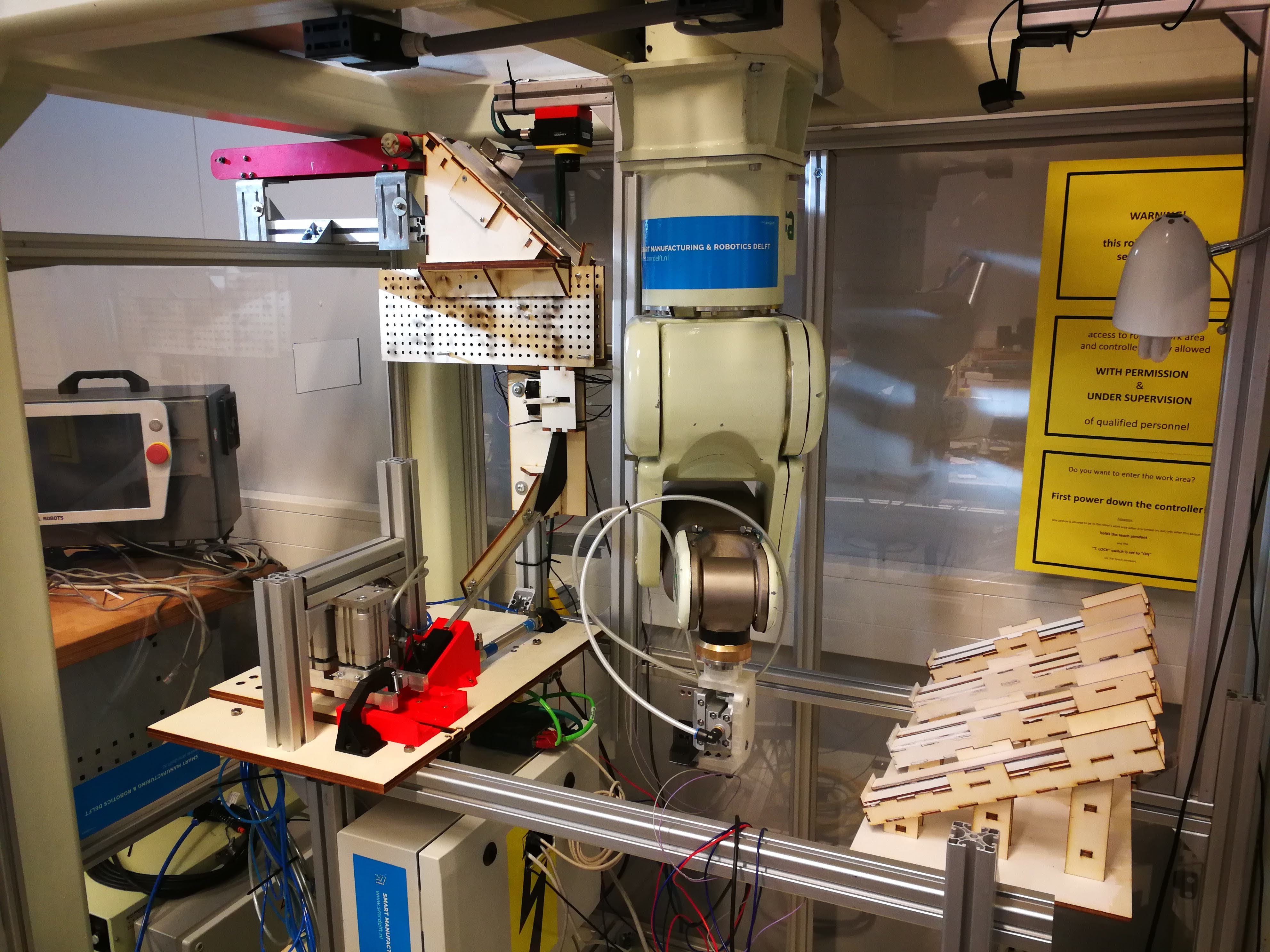

We are using a ceiling mounted Kawasaki FW03N robotic arm from the SMR lab at the The Hague University of Applied Sciences, Delft.

Goal

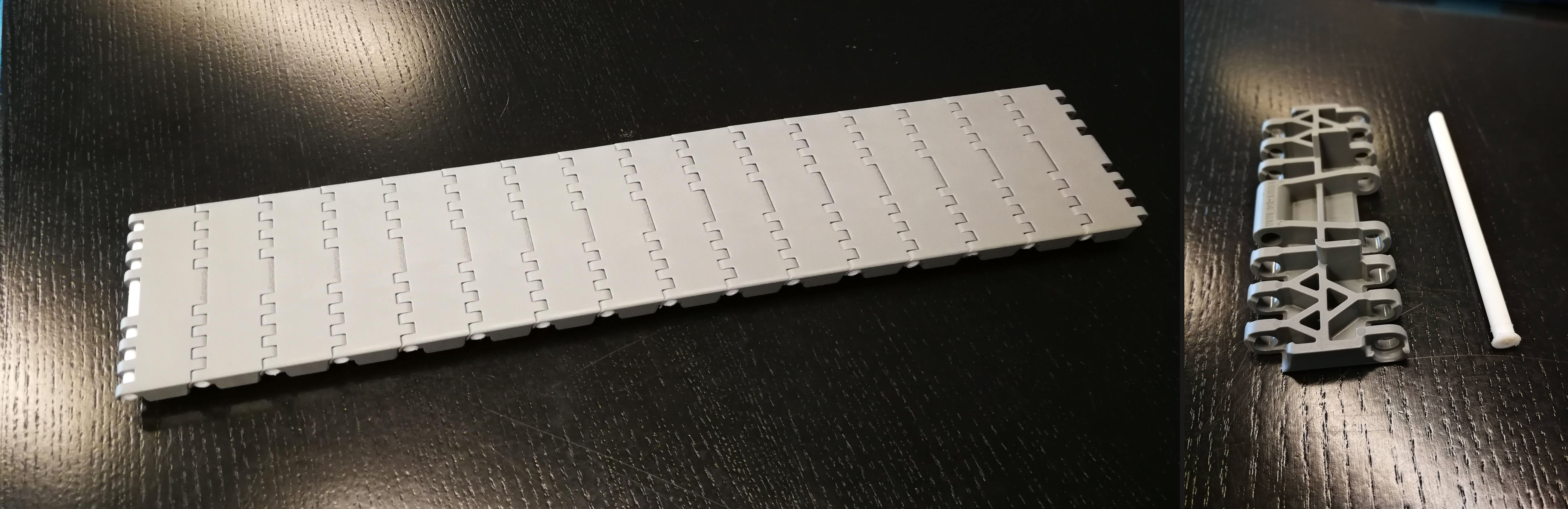

Rexnord wants a solution where a certain type of flattop module is assembled into a flattop conveyor belt (Rexnord PSX1001-84mm Series MatTop Chain). The modules are linked using pins.

In Rexnord’s factory, the modules arrive straight from an injection moulding machine on a conveyor belt. They arrive in different orientations at a rate of 8 modules per 32 seconds, or 1 module every 4 seconds. The modules are not checked for quality.

The pins are stored in a shaker bin that ejects one pin at a time. The pins have a thicker head that is used to click inside the modules so that they don’t drop out after insertion. This also means that the pins can only been inserted in one specific way. If the pin is inserted with the head first, the module or pin will break. The pinheads also have to be checked for quality. A small portion of the pins have incomplete heads (due to production failures), but one faulty pin weakens the whole chain so these have to be filtered out.

The assignment is to align the modules and insert a pin to create a flatop-chain. These pins need a quality check before insertion to filter out the faulty ones. We are aiming for an assembly rate of 1 module every 2 seconds, which is twice the factory’s speed of the delivery of the modules.

Approach

The created system has a lot of mechanical parts, divided in three subsystems.

1) FlatTop Pick & Place system

The FlatTop P&P exist of 4 module buffers. Using machine vision, the orientation and location of the modules are found and the robotic arm uses an End of Arm tool to pick up the modules. The picked up module is transported to a mold where it is clamped down. When a module is clamped, the robotic arm picks up a new module.

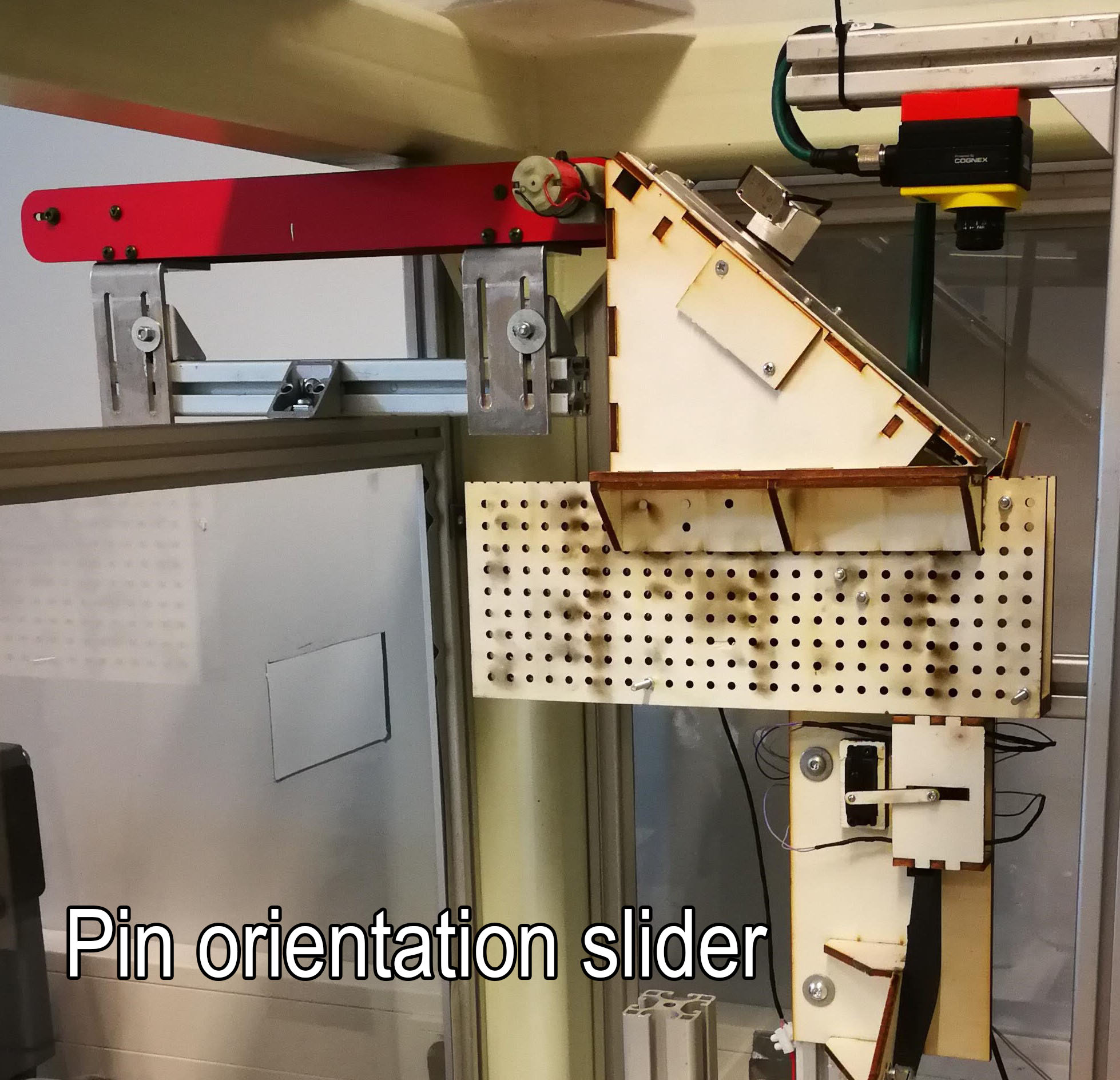

2) Pin Orientation Slider

The pins arrive on a conveyor in order to simulate the factory’s

shaker bin. The pins drop one at a time in a slider. The slide has a gap with the width of the pins, but not big enough for the head of the pin. This will cause the pins to hang on the edge of the head. At the end of the slide the pins drop down in a funnel with the heads up. The slide doubles as a filter for broken pin heads. Broken pins drop down the gap before reaching the funnel because the width of broken pins is not big enough for the slide. This filters about 90% of the broken pins.

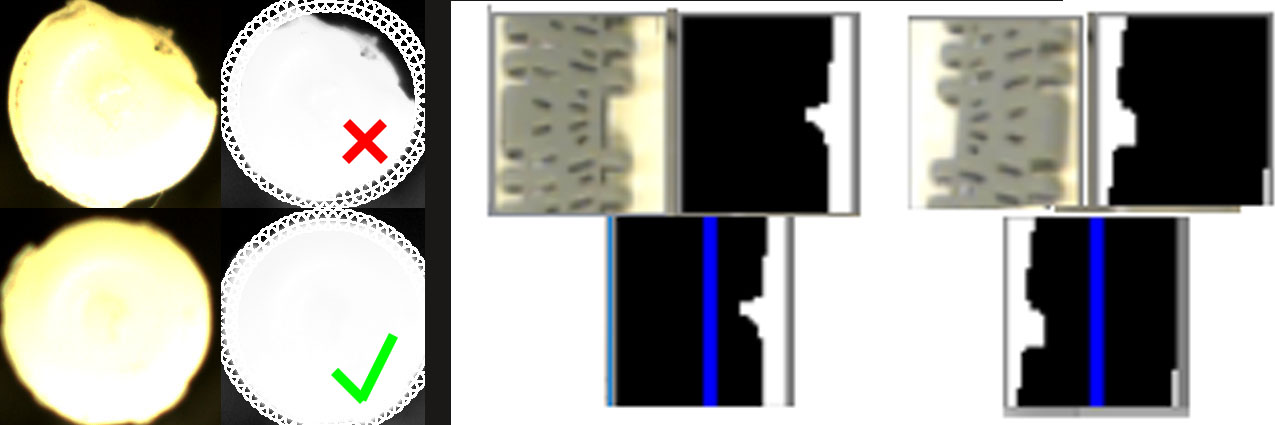

In the funnel is where a Cognex camera checks the top of the pin for quality. A set of DLR sensors in the funnel measures if the length of the pin is ok. If the quality and the length is correct the funnel slides to the left and the pin falls in a buffer, ready for insertion. If the quality is not good the funnel slides to the right and discards the pin.

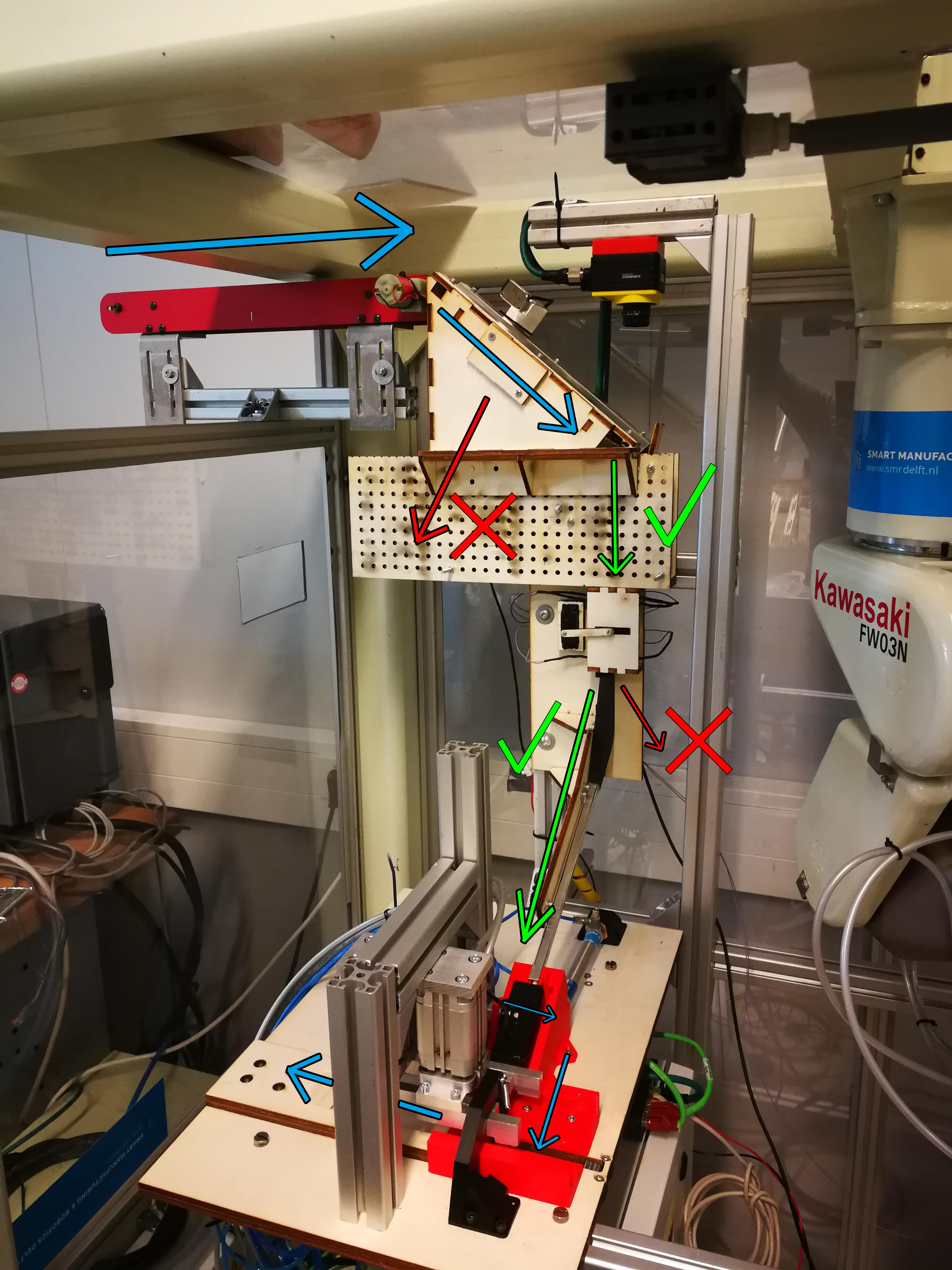

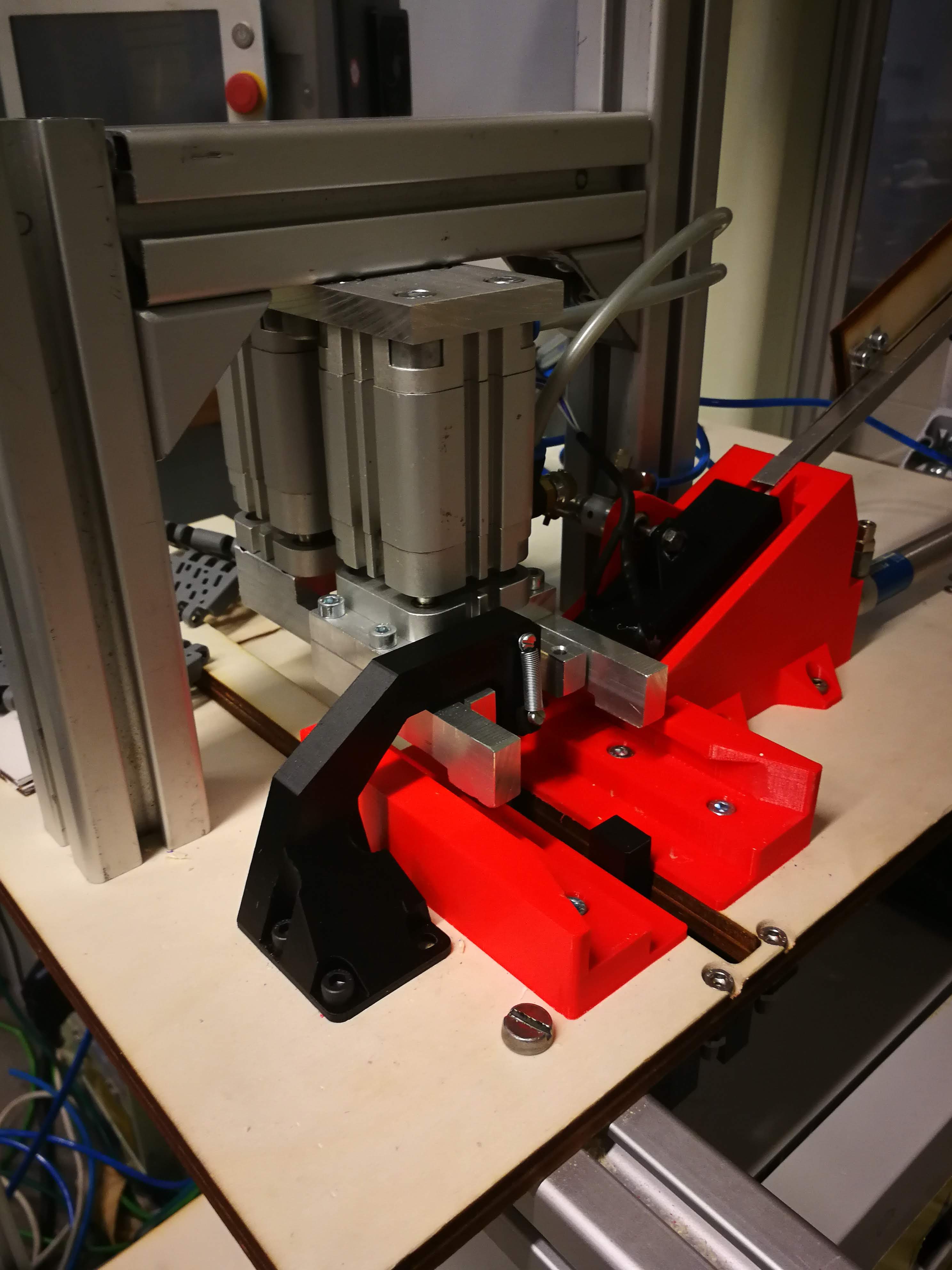

3) Pin Insertion System

The last part of the FlatTop assembly system is the insertion of the checked pins in the aligned modules.

A pin slides from the buffer into a subsystem that singles a pin out using a sliding part from the angled buffer. This positions a pin in line with the modules. A pneumatic actuator pushes the pin into the two aligned modules.

Two modules are held in place with clamps from the top of the mold. The is to make sure the holes of the modules are aligned with the hole where the pin comes from. Once the pin is inserted and the two modules are connected, a pushing block slides forward to push the modules a bit further to make place for the next module that the robotic arm delivers.

Vision

For the detection of modules and pins we’ve used two cameras. The quality of the head is the pins is checked using a Cognex In-Sight 7000 camera. A common defect in the pins is an incomplete head. Using circular comparison code in Python we can detect if a pin is faulty or not. Faulty pins get discarded using the funnel slider.

The robotic arm chooses on of the modules from the buffer using machine vision code and a Logitech HD Pro Webcam. The program can see the difference in orientation of the modules.

Results

The result of our system is a combination of pin orientation system, a quality check for pin length and head quality, module orientation, transport and pin insertion to create a flattop chain.