Students:

Freek van Dongen, Jordy de Schepper, Esther Killeen I Barberà, Gijs Polderman

Introduction

Ter Laak is a world leading orchid grower, situated in Wateringen, The Netherlands. By making use of technological innovations Ter Laak keeps working on their product and tries to make their impact on the climate as small as possible while producing 8 million plants per year. As a high-tech grower, Ter Laak is always looking to improve upon their process and thus has approached us to come up with an improvement for inspecting the plants during their grow, and to decide when a plant is ready to produce flowers.

Current situation

Ter Laak has worked with other companies to make an embedded inspection system. However, they feel like this this system can be improved upon. Currently the plants get passed through a vision system that looks at the plant from above, estimates the size of the plant by looking at the leaf area that is visible from above and based on that, the system makes a decision whether or not the plant is ready to start producing flowers. With this system Ter Laak is able to scan 1500 plants per hour with an estimated successful rate of classification of 95%.

The problem

The problem is that the system with just this one parameter, is not possible to repeatably justify the choice made for each plant.

Ter Laak grows multiple cultivars of orchid, and the size and composition of each of these cultivars can vary drastically. This means it could be possible for a number of leaves to be hidden behind each other when seen from above so a big plant would be classified as too small, or the other way around and a small plant will be seen bigger than it actually is.

Our solution

The solution we came up with starts off with mostly the same hardware as is currently being used in the process. Starting with a top down view of the plant then a system to rotate the plant in any orientation and camera’s that look at the plant from the side.

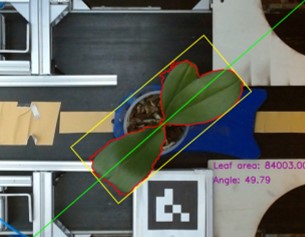

With the first (top view) picture the total visible leaf area is calculated as well as the angle of the plant relative to the other cameras. With this information the system calculates how far the plant should be turned so that in the next stage the plant is posed straight in front of the camera for the front and back pictures.

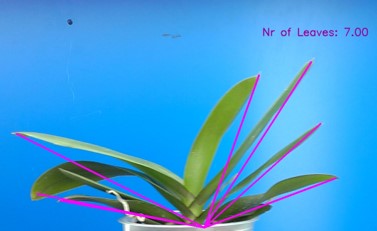

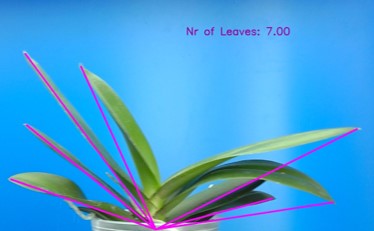

With these pictures we were able to calculate the height of the top-most leaf. And most important to Ter Laak, we were able to count the number of leaves on each plant to differentiate between “big enough” and “still too small” to produce flowers. Rule of thumb is: When a plant has produced more leaves, it is bigger and will produce more flowers which will result in a higher selling price.

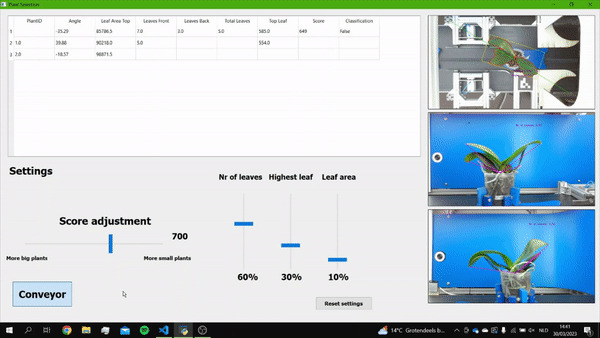

With these tree parameters, a score is given to each plant and the decision is made whether or not the plant is big enough or not depending on the position of the Score adjustment slider. With the slider Ter Laak can adjust the classification of the plants to regulate how much small plants there will be after the vision system. This is needed because the size of the plants can differ from week to week and they want a steady stream of big and small plants with about the same ratio of big and small each week.

Because the different cultivars display different properties in the parameters. We have made it possible for Ter Laak to select what parameters weigh more in the decision making in a simple HMI.

For cultivars that display less height but with bigger leaves it would be possible to tell the system that the leaf area is a more important parameter to look at. And for a plant that creates more leaves than others, Ter Laak could select the number of leaves to be more important to look at.

This way Ter Laak could set different profiles for the different cultivars to automatically select the correct weights of the parameters.

Results

In the end we were able to accommodate all of the wishes of Ter Laak,

Epilogue

We would like to thank Ewald de Koning and Raymond van Veldhoven for giving us this project and working with us. We would also like to thank Thijs Brilleman, Guus Paris and Mathijs van de Vegt for the tech support during the project.