spring 2022

Students: Gijs van Haeff, David Israel Maldonado, Jip Rasenberg and Imre Bakker

LinkedIn:

We would be happy to connect and answer your questions!

- Gijs van Haeff | LinkedIn

- David Israel Maldonado | LinkedIn

- Jip Rasenberg | LinkedIn

- Imre Bakker | LinkedIn

Introduction:

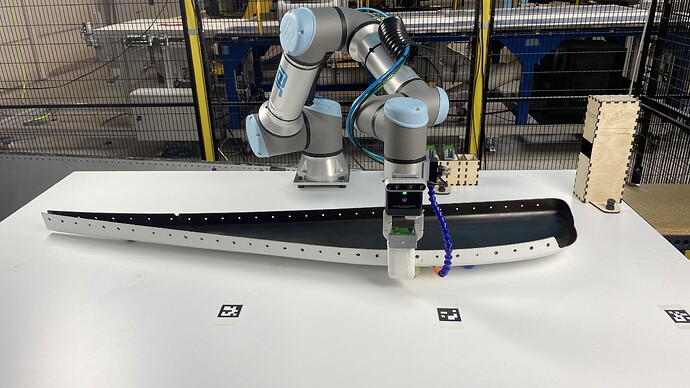

At SAM|XL in Delft, Fokker develops automated applications for the assembly of aerospace parts.

Parts need to be cleaned and degreased during the assembly process for proper bonding or painting. The vapours of the degreasing agents are extremely unhealthy. Therefore Fokker is looking for ways to automate the degreasing and cleaning process.The overall cleaning process takes place in Papendrecht, where multiple buildings are preserved for the assembly of aerospace parts.

The problem:

The degreasing agent is applied to surfaces which require bonding or painting. However, the solvent that is used is utterly unhealthy and has negative side affects when inhaled or exposed to the skin. This means that assembly workers and other employees that work nearby this degreasing agent require to wear safety equipment (masks, gloves, glasses etc.). The filters in these masks require to be replaced often, so does the other safety equipment. From a financial point of view this could lead up to huge amounts in the long term.

There are strict regulations to assemble aircrafts, therefore the employees must be trained and are required to follow assembly procedures. However there will always be a possibility of an human error. This could have a massive impact on the functionality of an aircraft. Summing up these issues will correlate to the following bullets:

- Unhealthy for employees.

- Masks/ filters are expensive over long time periods.

- Safety gloves and glasses are adding to the overall costs.

- Putting on and removing the protective equipment is time consuming.

- Human errors could lead to dangerous situations.

Besides these main issues the following technical issues occurred. These problems require to be solved in some way to ensure the functionality of a degreasing robot.

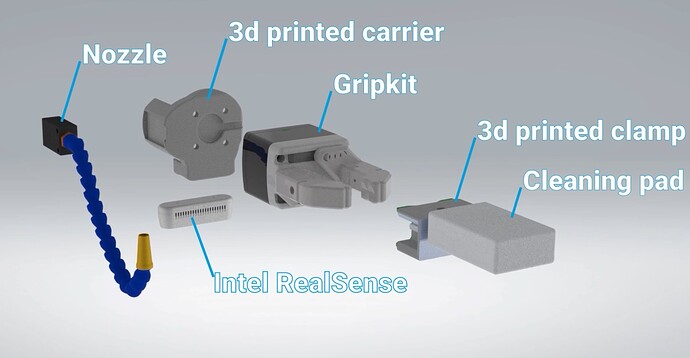

- A cleaning tool must be designed to be able to clean the bonding surfaces (aluminium, carbon fibres).

- Vision will be used to detect the cleanliness of this cleaning tool.

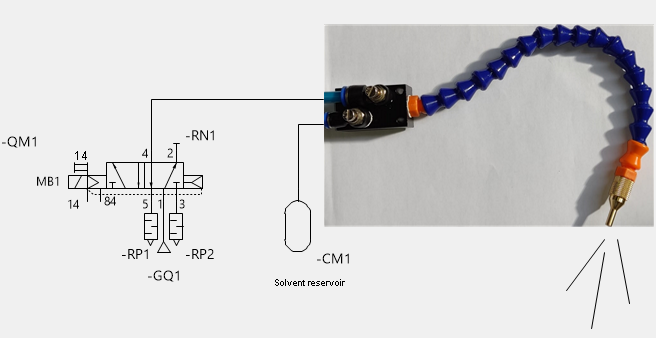

- Pneumatics are required to distribute the solvent on the tool/aircraft part.

- To fix the part for testing a clamping mechanism is required.

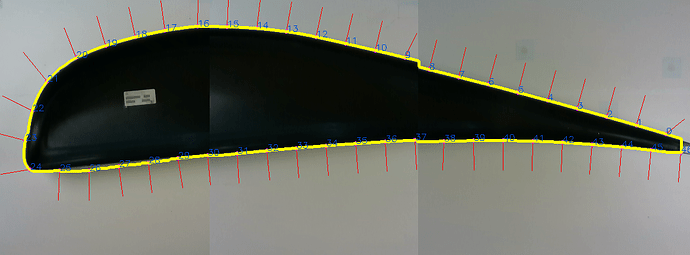

- To detect the orientation of the aircraft part

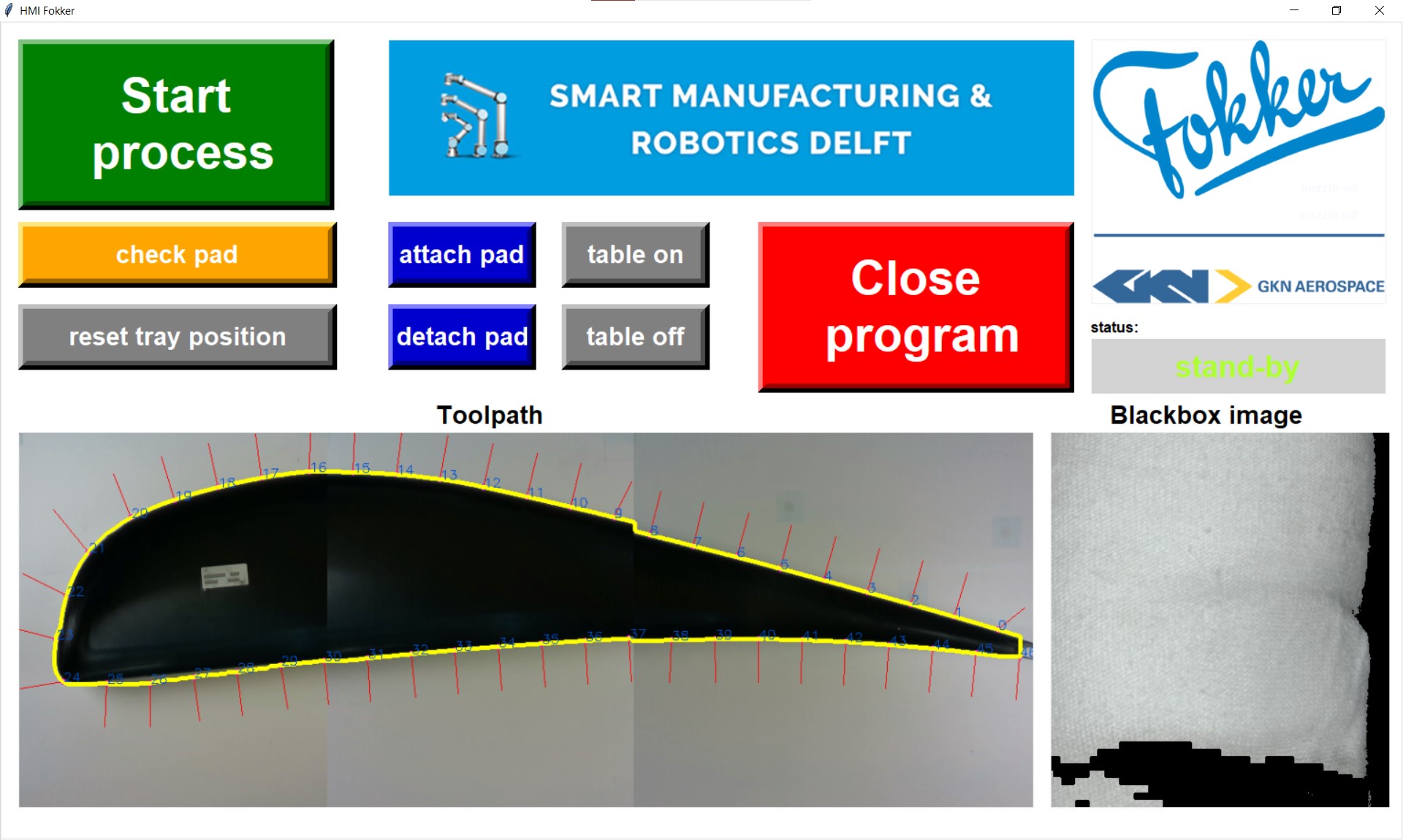

- An HMI to operate the cleaning process

- The overall communication of the robot and the vision systems.

Our solutions:

A robot arm has been selected to remove all safety, financial and time issues. In this early stage, a robot arm can easily prove the functionality and the concept of a cleaning robot. Thereby also providing the following solutions to our safety issues:

- Is not affected by the vapours of the degreasing agents

- Does not require replaceable safety equipment

- Could be more time efficient

- Reduces human errors

The technical solutions we came up with can be described as followed:

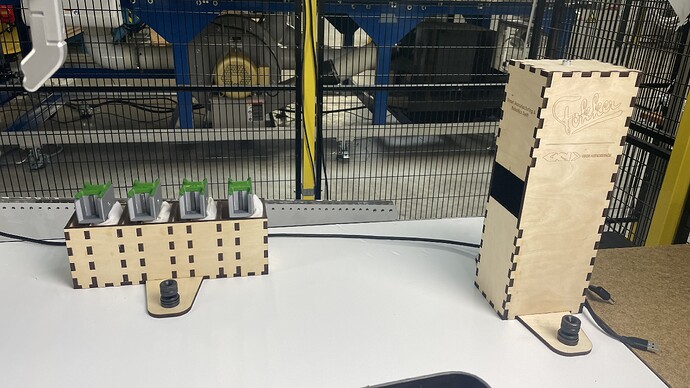

- Cleaning tool: A pad is designed which uses the same material as was conventionally used. A tray has been designed where the tool can be picked and placed if replacement is required.

- Grease detection: A “Blackbox” that has a mounted camera with lighting inside has been designed. The camera will create an HSV image of the tool which can filter out certain colours and light densities. When a certain percentage of oil/grease is detected, the robot will get a signal to replace the cleaning tool.

- HMI/Communication: An HMI with all cleaning functions is provided. Python is used to let the robot communicate with the HMI and vision modules.

- Distributing the solvent: The distribution is done by the use of pneumatics. The nozzle has two knobs that can be adjusted to change the ratio of air and solvent. The solvent will be sprayed on the part.

- Fixing the part: Pneumatic suction cups are used to hold the aircraft part in place.

- Part orientation: Aruco/QR markers are placed besides the part. Images are taken and are stitched to create a one image. An HSV filter is used to filter out the background. The contour of the part is detected. Along this contour multiple coordinates/waypoints are generated. Each point is provided with a vector which is perpendicular to the part, this represents the tool orientation. To decrease inaccuracies and increase consistent cleaning of the part, a force controller is used.

Recommendations:

There were many difficult decisions that our team had to make to come up with this end result.

-

EOAT design: Multiple EOAT concepts have been made. However these concepts seemed quite complex and not feasible. This resulted into a simple tool which worked fine to prove the concept. For later stages it might be interesting to test other solutions such as laser cleaning or adding rotating or vibrating components.

-

Lighting for vision applications: Currently, the lighting condition at SAMXL is unpredictable. This affects the current vision systems. It is suggested to use controlled lighting and background colours for future applications. Also more professional camera’s will increase the accuracy of the image detection.

-

Path following: Automated path generation leads to the detection of multiple shapes/parts, but also requires finetuning for each part individually. It is a nice feature, however for later stages hardcoded paths will be more suitable since all aircraft parts have a fixed location.

Conclusions:

All the issues that were found at the start of this project have been provided with a viable solution. According to a series of tests on an actual aircraft part, we can conclude that the robot efficiently cleans the bonding surface of an aircraft part. The robot can detect whether its cleaning tool requires to be replaced to ensure the cleaning quality. Due to the image recognition it is possible to detect other shapes as well. However if these parts need to be cleaned, they require some additional tuning before the program can run. Since all issues have been solved we can conclude that the proof of concept for a degreasing robot has been a success.

Epilogue:

We would like to thank our supervisor Jan Baan for his great input to this project. Jan is really creative, and experienced as we have noticed and it has been great working with him throughout the whole project. Also we would greatly like to thank SAM|XL for using their facilities and tool during this project. Besides that, we would like to thank Mathijs van der Vegt, Guus Paris and Thijs Brilleman for their technical support and feedback.