Students: Dave Cheung, Margot Driessen, Niels Goos, Deividas Stravinskas

GitHub: https://github.com/nielsgs/LanduwascoSMR2

Introduction

Landuwacso is going to release a new system that will overtake the manual process of filling the towel containers that is now done by hand. The system will use a cobot for picking and placing the towels in a container feeder, this feeder will then fill the towel container levels with a full loading container.

The main problem here is that every container filling process is done manually. This means that people are necessary to do these kinds of monotonous jobs, this will result in quality and effectiveness loss over time.

Another problem is that for filling the containers with towels and other fabrics a big sorting system is needed. This system contains a lot of transport belts and a big silo for storing and transporting these different fabric bundles, this takes up a lot of space.

The last problem to discuss is safety, when working in a fabric there are always risks of getting injured by machine or just by the physical work being done. That is also an important but overlooked reason to automate this process.

Requirements

To automate this process a few points have been taken into consideration; Speed is important because the industrial laundries handle over hundreds of towels per hour. The filling process is important because the containers have to be filled as optimally as possible, without compensating for neatness/tidiness in the cart.

What is also taken into consideration is the adaptability of the system to be used for other kinds of towels, blankets or other kinds of laundry.

The automated solution

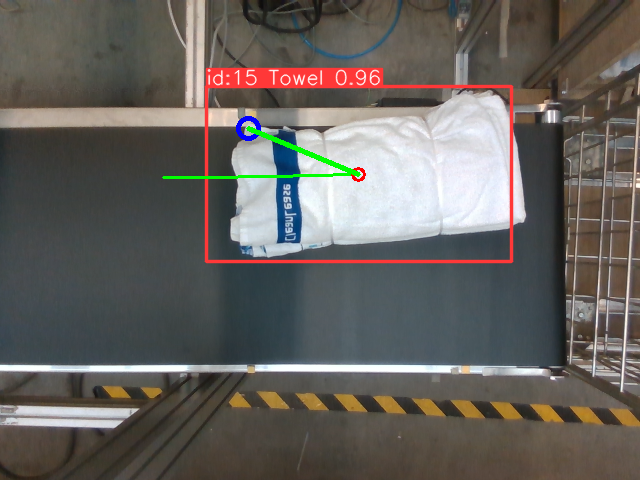

In this process we start with towel bundles that just came out of the folding and strapping machine on a conveyor belt. Our system uses object detection and tracking to detect the towel bundles and its location. This is done with Ultralytics Yolov8 and Python.

Figure 1: Towel detection using Ultralytics YOLOv8

The automated process uses a Doosan Cobot with our own design of an EoAT (End of Arm Tool). This tool is a gripper that is able to pick up the towels and also compress them. The compressing is an important feature for filling the container optimally. Because of this 4 bundles fit horizontally in one container level. Next The cobot stacks the towelbundels in a towelfeeder.

Figure 2: End of arm tool Figure 3: Towel loader

The cobot uses a sweep function to neatly place the towels (see video). The towelfeeder uses a system with pneumatics and is able to unload the towel bundles for an entire level at once. The towelfeeder first moves the towel plate with the towel bundles into the container, then another piston is activated which pushes the towels into the container while the other piston with the towelplate retracts.

Advantages and result

The use of the towelfeeder instead of filling directly in the container with the cobot has multiple advantages. It’s faster because the path the robotarm follows is shorter, it’s more consistent, the containers have slight differences and wear, which can cause difficulties Also, the cobot needs less reach than when it would have to fill the outer corners of the container.

Next to this, it’s more versatile because this system can also be used for other kinds of laundry.

Figure 4: End result of automated process